25

Apr 2016

Controlling Wood Dust

Controlling Wood Dust – Acoustic Flooring

Wood dust dangers

The Health and safety at work act 1974 states that “it is the duty of every employer to ensure, so far as is reasonably practicable, the health safety and welfare at work of all their employees.”

One current area of interest to HSE (Health and Safety Executive) is the control of construction dust. Wood dust is the primary type of dust created when installing a floating floor. Wood is widely used in construction and is found in two main forms; softwood and hardwood. Wood-based products are also commonly used including MDF and chipboard.

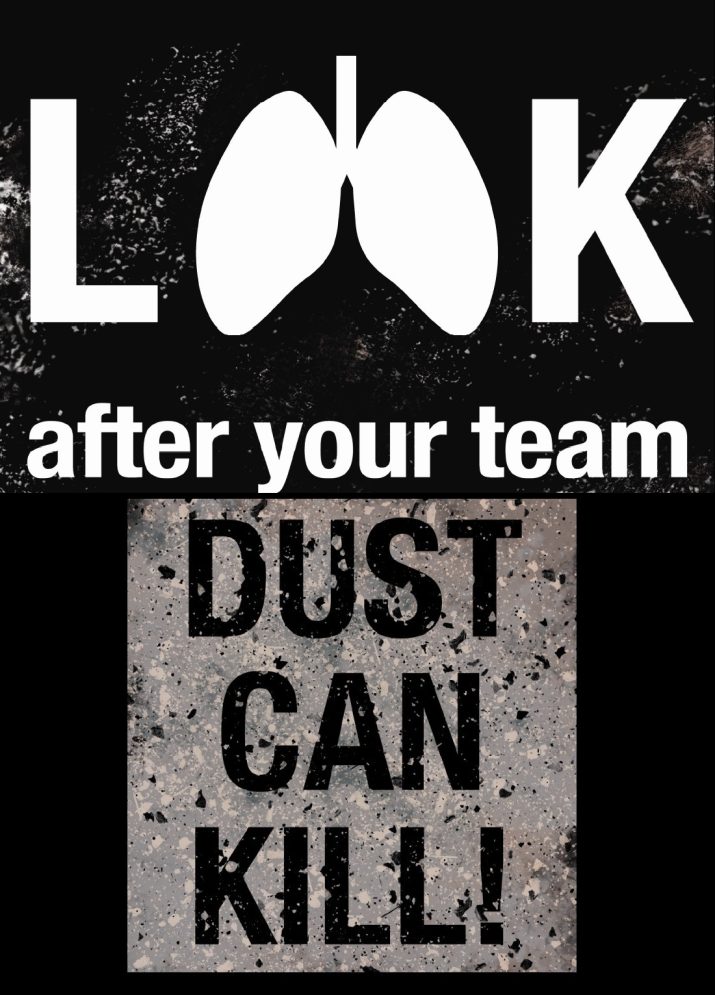

JCW have decided to support the ‘Breathe Freely’ campaign to raise awareness of the dangers of preventable occupational diseases caused by wood dust.

A recent report found that more than 7,000 occupational cancer deaths a year are caused by dust exposures in construction, this equates to 1 in 20 cancer deaths in the UK, not to mention other conditions such as asthma which can develop through wood dust inhalation.

Controlling Wood dust

The primary way to control wood dust like any other hazard is to eliminate where possible. If this is not possible the correct type of dust extraction system is imperative. When cutting softwood an M-class dust extraction system should be used. When cutting hardwood dust a H-class dust extraction system should be used.

In addition to this, the correct PPE should be worn. It is no longer enough to simply wear a dust mask. The correct dust mask must be worn, FFP3 dust masks should be worn when cutting wood products. All operatives should be trained by a competent person to ensure that they are used correctly and replaced at the correct intervals.

FFP3 Filtering mask can help prevent dust inhalation

All dust masks should also be face fit tested for each operative to ensure that the mask is working correctly. Dust masks rely on a tight seal with the face to work. If the mask does not fit properly the dust can slip through any gap between the mask and the face and into the airways. Dust particles can be much smaller than the width of a hair so the face seal needs to be very good.

At JCW Acoustic Flooring, the health safety and welfare of all our operatives is paramount. All JCW Acoustic Flooring operatives have been face fit tested and are all supplied with M-class dust extraction systems. Regular toolbox talks are carried out to ensure that all operatives are familiar with the correct use and maintenance of their RPE (Respiratory Protective Equipment).

Qualitative fit testing as stated in HSG53

Further to this, our contracts manager Paul Hayes is qualified to perform qualitative face fit mask testing under the Fit2Fit RPE test accreditation scheme. This allows JCW Acoustic Flooring to regularly test and fit masks on an ongoing basis.

Qualitative fit testing is a pass/fail test based on the wearers subjective assessment of any leakage from the face seal region, by sensing the introduction of a test agent.

For more information, on JCW Acoustic Flooring installations please call us on 01204 387029